Overview

The development and commercialization of active pharmaceutical ingredient (API)drug candidates require partnership with a trusted contract development and manufacturing organization (CDMO). Our experienced process chemists, engineers, analysts and operations teams in High Point focus on the development, commercialization and manufacture of active pharmaceutical candidates currently progressing through mid- to late-stage clinical trials. We offer a variety of services in support of GMP API development, validation, and manufacture, working in our newly renovated, state-of-the-art chemistry laboratories and manufacturing facilities. Our site specializes in the manufacture of small-volume commercial products (typically needing less than 500kg API/year), and we are also licensed with the US Drug Enforcement Administration (DEA) to manufacture Schedule II to Schedule V controlled substances.

Facility Details

- Plant reactors ranging from 400 L to 2,000 L for nGMP or GMP API manufacture

- Temperature ranges from -70°C to +160°C, covering a wide variety of challenging chemistries

- Well-equipped process chemistry laboratory featuring jacketed glass reactors, automation chemistry systems, advanced process modeling software, DOE, PAR, NOR and F&P expertise.

- Includes 65 bench hoods, 8 walk-in hoods and 100 L reactors for robust process demonstrations

- Complemented by a comprehensive suite of walk-up analytical and in-situ reaction monitoring equipment.

- Process engineering laboratory supporting the mockup and fabrication of continuous flow reactor skids, comprehensive process safety evaluation and advanced process modeling support

- Extensive suite of jacketed kilo-scale reactors ranging from 5 L to 100 L for nGMP, laboratory-based demo batch manufacture

- Controlled substance R&D and manufacturing capability for Schedule II to Schedule V

- GMP-compliant chemical storage with quarantine for raw materials, intermediates and finished products

- Robust quality platform supporting the manufacture of commercial products in parallel with a nimble clinical API development program

Personnel

- Technical project management – a core strength with Ph.D. Project Managers averaging over 15 years in the industry

- Strong process chemistry team composed of highly experienced scientists, the majority holding Ph.D. degrees, with deep expertise in process robustness

- Experienced analytical development team proficient in fit-for-purpose, analytical method development and validation in support of commercial products

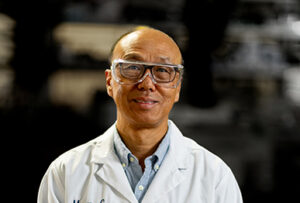

Meet one of our High Point experts

Myoung Goo Kim

With an extensive background in process development and optimization, route scouting, and technology transfers, Myoung Goo is a recognized expert in process chemistry and plays an instrumental role in successful API manufacturing for clients.